Sterilizer machine is an advanced solution designed to maintain optimal hygiene standards within a production facility. It is engineered to eliminate all forms of microorganisms through the process of sterilization, including harmful pathogens, viruses, spores, bacteria, and fungi. A sterilizer machine reduces microbial load and enhances safety, reliability, and efficiency.

Sterilization plays a critical role across various industries. Many businesses depend on highly engineered, technologically advanced equipment to meet strict hygiene and safety requirements. Among the many machines available on the market, the most widely used is the industrial sterilizer, which operates with hot water at temperatures ranging from 65 to 110 degrees Celsius.

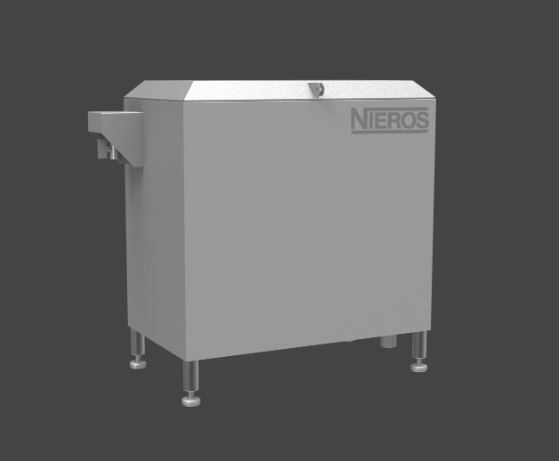

This equipment is carefully designed to support both practical use and the technical demands of effective sterilization. Solutions such as knife sterilizers are made of high-quality stainless steel, capable of withstanding pressure, chemical exposure, high temperatures, and water. To ensure safe operation, these units include essential safety features and comply fully with relevant laws and industry regulations.

How to Integrate Knife Sterilizers Into the Facility

Knife sterilizers are critical pieces of equipment used across multiple industries. Without effective sterilization, knives can become carriers of microorganisms, jeopardizing product quality, safety, and compliance. Installing such a solution within the facility helps prevent the spread of pathogens such as Salmonella and Listeria. There are various safeguards available to reduce cross-contamination, and the right choice depends on specific hygiene requirements, facility layout, and the type of product being handled.

When implementing a sterilizer machine in the production environment, it is essential to consider accessibility, hygiene flow, and ergonomics. The unit should be positioned within easy reach of the workstation. Poorly placed equipment can create bottlenecks, so the setup must support workflow and operational cycles without interruptions. Proper integration into the facility’s utility systems is also crucial to ensure continuous operation.

Most companies have rigorous safety and hygienic standards, meaning an industrial sterilizer must be integrated into regular cleaning and maintenance protocols. Incorporating sterilization into daily routines enhances both operational continuity and overall performance.

An Industrial Sterilizer That Meets Sustainability Requirements

A sterilizer machine is a cleaning solution designed to ensure optimal hygiene of equipment across a range of industries. It complies with HACCP, IFS, and NSF standards while meeting demanding hygiene requirements. The machine is used to disinfect tools such as axes, saws, knives, knife baskets, and aprons, supporting the highest sanitation protocols.

Engineered from high-quality stainless steel (DIN 1.4301 / AISI 304), the equipment offers long-term durability and supports sustainable practices. It helps reduce operational costs through efficient time usage and minimal energy consumption. Knife sterilizers are compact and adaptable, making them suitable for any production area, including those with limited space. They feature double-insulated walls and use hot water for sterilization, with temperatures between 65°C and 110°C, controlled by an adjustable thermostat. A heater burnout protection device is also included to enhance operational safety.

This functional, space-saving equipment is available in two models, accommodating between 5 and 15 large, and 10 to 30 small knife baskets. Thanks to premium in-house design, the appliances minimize contamination risk and meet the highest quality and hygiene standards.

Why Are Sustainable Solutions Important in Industrial Environments?

An industrial sterilizer must ensure optimal safety and align with modern energy and environmental standards. Today, businesses face increasing pressure from regulatory bodies to implement sustainable practices. These requirements are directly linked to operating costs and carbon emissions. As manufacturers, we carry a significant responsibility to develop solutions that meet sterility standards while minimizing energy consumption.

When multiplied across thousands of cycles per year, even small reductions in energy use per cycle can lead to substantial environmental and financial benefits. Sterilization remains a critical step in maintaining hygiene and safety, and it cannot be removed from the process. At NIEROS®, we have re-engineered our appliances to be more energy-efficient without compromising effectiveness. Any waste of energy during disinfection results in unnecessary costs and emissions.

A NIEROS® sterilizer machine is designed to achieve high sterility levels with minimal energy input. It enables facilities to adjust sterilization cycles as needed, while its double-insulated wall construction helps retain heat and prevent energy loss. The energy-efficient design not only reduces consumption but also extends the equipment’s lifespan and lowers maintenance and replacement costs.

Durable, Reliable, and Sustainable Industrial Sterilizer

Knife sterilizers are highly automated machines that ensure tools used within a facility meet the highest hygiene standards and regulations. Built from high-grade stainless steel, they are durable, reliable, and sustainable. In today's regulatory climate, sustainability is a key factor in selecting the best solution. Governments worldwide are introducing stricter environmental policies, requiring industries to adopt more sustainable practices.

Technologically advanced equipment from NIEROS® features ergonomic and hygienic design, effectively eliminating microorganisms through heat. Integrating a sterilizer machine into a production requires careful planning of utility connections, placement, maintenance, and monitoring. With an adjustable thermostat and double-insulated wall construction, it can reduce contamination risk with minimal time and energy consumption.

At NIEROS®, we continuously invest in our advanced R&D department, allowing us to offer tailored solutions for a wide range of operational challenges. We support our clients in meeting industry standards while helping them optimize time and cost efficiency. Through ongoing development, we continue to meet the evolving needs of multiple industries. For more information on our products, do not hesitate to contact us.