Footwear cleaning machines have gained prominence as an efficient and effective solution for ensuring proper cleanliness in production plants. Maintaining clean and hygienic footwear is of paramount importance across various industries. There are major advantages to utilizing a footwear cleaning machine for companies that invest in this piece of equipment.

Enhanced hygiene standards: an industrial footwear cleaner enables companies to establish and maintain high hygiene standards. By removing dirt, dust, and contaminants from footwear, these machines minimize the risk of cross-contamination, ensuring a clean and safe working environment.

Improved productivity: with automated cleaning processes, an industrial footwear cleaner can save time and effort for both employees and management. This leads to increased productivity as employees can quickly clean their footwear before entering controlled areas, eliminating the need for manual cleaning methods.

Cost efficiency: by investing in a top-quality device, companies can reduce expenses associated with manual cleaning supplies and labor. The automated process eliminates the need for dedicated personnel or time-consuming manual cleaning, resulting in long-term cost savings.

Which industries can benefit from an industrial footwear cleaner?

Let us have a look at the sectors where these products can really make a difference and lead to a higher level of trust in the brand.

- Food processing and manufacturing: maintaining hygiene and preventing cross-contamination are critical in the food industry. An industrial footwear cleaner ensures that employees entering food-processing areas have clean and sanitized footwear, minimizing the risk of foodborne illnesses and upholding strict regulatory requirements.

- Pharmaceutical and healthcare: in pharmaceutical and healthcare settings, where sterile environments are crucial, footwear-cleaning machines play a vital role in preventing the introduction of contaminants. These machines help maintain a clean environment, reducing the potential for cross-contamination and ensuring the safety of patients and employees.

- Cleanrooms and electronics manufacturing: cleanrooms and electronics manufacturing facilities require stringent cleanliness standards. Footwear cleaning machines aid in maintaining the desired level of cleanliness by preventing the entry of particulates and static discharge that could compromise sensitive equipment and delicate electronic components.

What are the footwear cleaning benefits for staff and management?

Convenience and time savings: shoe cleaning machines offer convenience and efficiency for both staff and management. Employees can easily clean their footwear by simply stepping on the machine, saving time and effort compared to manual cleaning methods. Management benefits from streamlined processes, reduced labor costs, and improved overall operational efficiency.

Employee safety and well-being: clean footwear plays a significant role in ensuring employee safety. Footwear cleaning machines remove potential hazards, such as slippery substances or contaminants, reducing the risk of accidents and injuries. By providing a safe working environment, companies can prioritize employee well-being and foster a positive workplace culture.

What are the dangers of not using footwear-cleaning equipment?

While the advantages of using the right devices are evident, it is equally important to recognize the potential dangers and risks associated with not implementing them. Failing to use proper machines can have severe consequences for companies across various industries. An increased risk of contamination and compromised workplace safety are just some of the consequences that your company can face if it does not invest in the right equipment.

Without proper and adequate cleaning measures in place, contaminants from external environments can be carried into sensitive areas. This increases the risk of cross-contamination, potentially leading to product contamination, compromised quality, and costly recalls in industries such as food processing, pharmaceuticals, and electronics manufacturing.

In industries where hygiene is paramount, such as healthcare and cleanrooms, the absence of proper cleaning equipment can facilitate the spread of pathogens. Bacteria, viruses, and other harmful microorganisms can be transported into sterile areas, endangering patients, compromising research integrity, and potentially causing outbreaks of infections.

Accumulated dirt, moisture, and contaminants on shoes increase the likelihood of slip-and-fall accidents. Inadequate hygiene practices can lead to slippery surfaces, posing risks to employees and visitors. These accidents can result in injuries, productivity losses, and potential legal liabilities for companies.

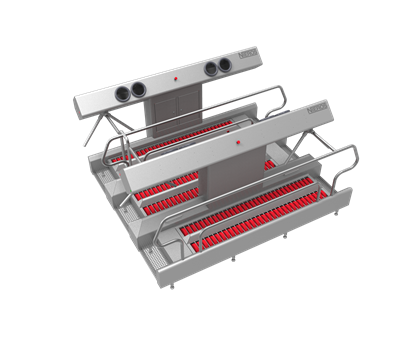

Watch out for the top-quality materials used in footwear cleaning items by Nieros

Nieros places great value on using the highest-rated materials for its equipment, among them:

- Stainless steel: high-quality cleaning machines are constructed using durable stainless steel. Stainless steel offers excellent resistance to corrosion, ensuring longevity and minimizing the risk of contamination. Additionally, stainless steel is easy to clean and maintain, making it an ideal choice for hygiene-focused equipment.

- Non-slip surfaces: the top surfaces of cleaning machines should feature non-slip materials to prevent slips and falls during the cleaning process. This enhances user safety and minimizes the risk of accidents in the workplace.

- Chemical-resistant components: To withstand regular cleaning and disinfection, these cleaning devices utilize chemical-resistant materials. These materials ensure that the machine remains durable and functional even when exposed to various cleaning agents.