Hygiene systems are advanced monitoring tools that are transforming industrial operations. Modern equipment has redefined how facilities approach operational efficiency, safety, productivity, and hazard response. When integrated with smart technology, these systems ensure maximum sanitation in industrial and manufacturing environments by preventing the entry and spread of germs, bacteria, and harmful pathogens.

Most industries have rigorous sanitation standards, and handwasher represents the first line of defence. Hands are a breeding ground for bacterial and microbial growth, which can cause serious harm. A specialised comprehensive solution eliminates risks with meticulous design, allowing personnel to wash their hands and boots upon entering or exiting the production area.

Implementing a hygiene station ensures consistent practices and improves overall efficiency. Proper hand-washing and sanitising can be time-consuming, but a dedicated wash station streamlines the process, delivering faster, more thorough, and reliable results. Preventing cross-contamination is especially critical in industrial environments (particularly in food processing) where hygiene lapses can lead to serious health risks and potential legal consequences.

Hygiene systems are worth the investment when placed with intention and installed correctly

A hygiene station is essential in modern manufacturing facilities, helping to minimize the spread of contaminants and ensure optimal safety. Designed with innovation in mind, these comprehensive systems typically include wash basins, disinfection units, footwear cleaners, and dryers. At NIEROS®, we design and manufacture a wide range of hygiene solutions that reduce cross-contamination and limit the spread of workplace-borne illnesses. Since every facility has unique requirements, we also offer fully customized solutions tailored to your operational needs.

While hygiene systems represent a significant investment, the real question is: Is it worth the cost? Absolutely. The initial outlay delivers a fast return by improving safety, ensuring compliance, and streamlining operations.

For example, a handwasher enforces mandatory hygiene protocols and helps facilities meet critical regulations, standards, and legal requirements without deviation. When properly installed and strategically placed, these systems are highly effective. Failing to meet hygiene standards can result in operational bottlenecks, financial losses, and serious health risks.

A handwasher will help you comply with all regulations, laws, and requirements

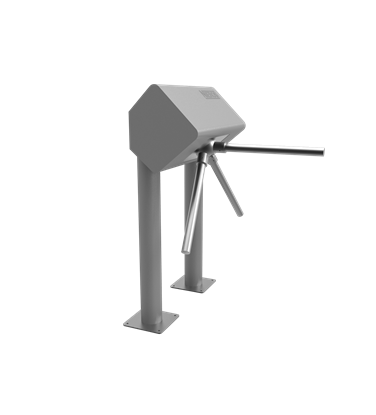

Handwasher provides optimal sanitation upon entering the production area. The standardised process begins with effective soaping and thorough rinsing, followed by hand drying and disinfection, which destroys harmful pathogens. The procedure is planned meticulously, directing personnel to follow each step. A turnstile-controlled passage at the end guarantees no one is missing a step.

A stringent sanitation plan prevents cross-contamination. It also ensures the facility complies with the necessary standards, such as HACCP, NSF, and IFS. At NIEROS®, we offer a broad range of high-quality hygiene systems. All of our products have an ergonomic design, combining multiple functions in one. We implemented several sustainable practices, and our goal is to produce environmentally friendly products.

Our hygiene solutions are constructed from premium stainless steel - DIN 1.4404 (AISI 316Ti) and DIN 1.4571 (AISI 316L). Designed with hygiene in mind, they feature a smooth surface finish and are available in a wide range of models to suit various operational needs.

A hygiene station incorporates hand disinfection and boot cleaning

Hygiene systems offer hand disinfection and footwear cleaning. Boot cleaners are outstanding solutions for facilities where clean footwear is paramount. The equipment we design is simple to use, highly efficient, swift to proceed, and cost-effective. The equipment is height-adjustable and available in numerous models, different cleaning line lengths, and with various types of brushes. The latter can clean the sides, soles, or the entire boot.

Boot cleaners have horizontal brushes for cleaning the soles and vertical brushes for cleaning both sides of the boots. Push button activates the brushes. We designed a broad range of add-on units that complement standard versions. Because our products are manufactured in-house, they can be fully customised and adapted to different electric power distribution systems. Each hygiene station is designed to reduce contamination risks, align with specific cleaning processes, and minimize energy consumption.

A handwasher reduces bacterial transfer in sterile zones

A hygiene station is required by law in most industrial facilities. As one of the leading manufacturers, we are aware of the impact hygiene has on crucial metrics, including productivity, compliance, safety and profitability. Adequately installed sanitation solutions prevent regulatory violations, extend machine life in the sterile zone, minimise contamination risk, and reduce downtime.

Sanitation solutions also protect the personnel and simplify workflows. Because our hygiene systems are produced in-house, they can be tailor-made to perfectly fit your facility and business requirements. Our mission is to design and manufacture the ideal solution that improves user experience and maximizes hygiene efficiency.

We have been successfully combining tradition with advanced techniques for over 250 years. Our goal is professional development, which is why we invest in our R&D department and personnel. To provide the best service and to find unique products, we are expanding our capabilities with the environment in mind.