A shoe cleaning machine serves as a crucial first line of defense against contaminants. When chosen or designed correctly, it becomes a dependable component of your hygiene protocols. In manufacturing a washing solution, it is vital that its design and engineering align with your business needs, as these factors determine operational effectiveness and enhance overall control. Selecting machinery with optimized nozzle configurations, diverse brushes, efficient components, and adjustable settings can also deliver significant long-term savings.

Footwear cleaning is an essential practice in industrial environments, as soles often carry contaminants, bacteria, debris, harmful pathogens, dirt, and dust. Investing in a high-quality boot cleaner station provides a wide range of operational, financial, hygiene, and safety benefits. By ensuring consistent washing performance, these systems reduce contamination risks, support regulatory compliance, and help streamline workflow.

9 Hygienic Design Principles for a Boot Cleaner Station

A shoe cleaning machine plays a critical role in establishing and maintaining effective hygiene protocols. Even a single pair of contaminated boots can jeopardize staff safety, product integrity, and regulatory compliance. A hygienic design helps prevent dirt, microorganisms, and other contaminants from moving between production or manufacturing zones. To achieve this, manufacturers must consider several key design principles:

- Ensuring a seamless flow of staff

- Establishing controlled movement patterns

- Using hygiene-focused materials and surfaces that are easy to clean

- Providing optimal water control and fluid management

- Customizing mechanical action and components to fit the specific boot design

- Structuring cleaning sequences to separate mechanical brushing from sanitizing to prevent cross-contamination

- Prioritizing robust, durable, ergonomic, and reliable engineering

- Incorporating automation for consistent hygiene practices

- Meeting quality and industry-specific compliance standards

Best Practices for Installing Footwear Cleaning Solutions

A boot cleaner station is an excellent addition to any industrial setting. These environments demand disciplined hygiene control. To prevent cross-contamination, many facilities are installing modern washing solutions that support regulatory compliance and enhance overall safety. Before implementing such machinery, it is essential to analyze the specific risks the equipment should address. While the food and beverage industry focuses heavily on microbial and allergen contamination, heavy industries encounter different types of hazards. By pinpointing the sources of contamination, you can determine where cleaning equipment will be most effective.

When integrating new apparatuses, it is important to evaluate foot traffic, as the device you select must support continuous movement. By identifying risks and calculating the required throughput, you gain the insight needed to choose the right shoe cleaning machine. To maintain strong hygiene protocols, careful installation planning and, when necessary, customization are crucial. Tailoring the machine ensures seamless implementation and encourages staff adherence to established protocols.

Understanding Flow Rate in Industrial Footwear Washing Systems

A shoe cleaning machine uses sanitizer distribution and controlled water movement to remove contaminants. The flow rate is crucial because it governs how water moves through the wash system. Although it may seem insignificant, flow rate influences energy consumption, long-term reliability, drainage requirements, chemical dosing accuracy, and overall cleaning power. A stable flow rate supports compliance, extends equipment lifespan, and improves cleaning consistency.

The flow rate is expressed in liters per minute. As water moves through the brush housings, it affects spray intensity, sanitizer distribution, and the effectiveness of contaminant removal. Automatic footwear cleaning apparatuses achieve the highest performance. Engineering factors that determine flow rate include pump capacity, inlet pressure, nozzle size and configuration, pipe diameter and layout, brush design, chemical dosing system, and drainage integration.

Why is a Boot Cleaner Station Worth the Investment?

Footwear cleaning systems help industries adhere to strict regulations, laws, and standards. As a global manufacturer, we recognize the critical role these apparatuses play. For over 250 years, we have developed and produced cost-effective, customized solutions for numerous sectors, including agriculture, petrochemical, food and beverage, pharmaceutical, transportation, chemical, automotive, and many others.

We can confidently say that a shoe cleaning machine is a worthwhile investment. It provides a level of personnel hygiene consistency that manual processes cannot match. The equipment reduces cross-contamination between sterile work zones, enhances workplace safety, ensures regulatory compliance, and boosts productivity. It also delivers consistent sanitizer application, controlled chemical use, protection for sensitive production equipment, and long-term cost efficiency.

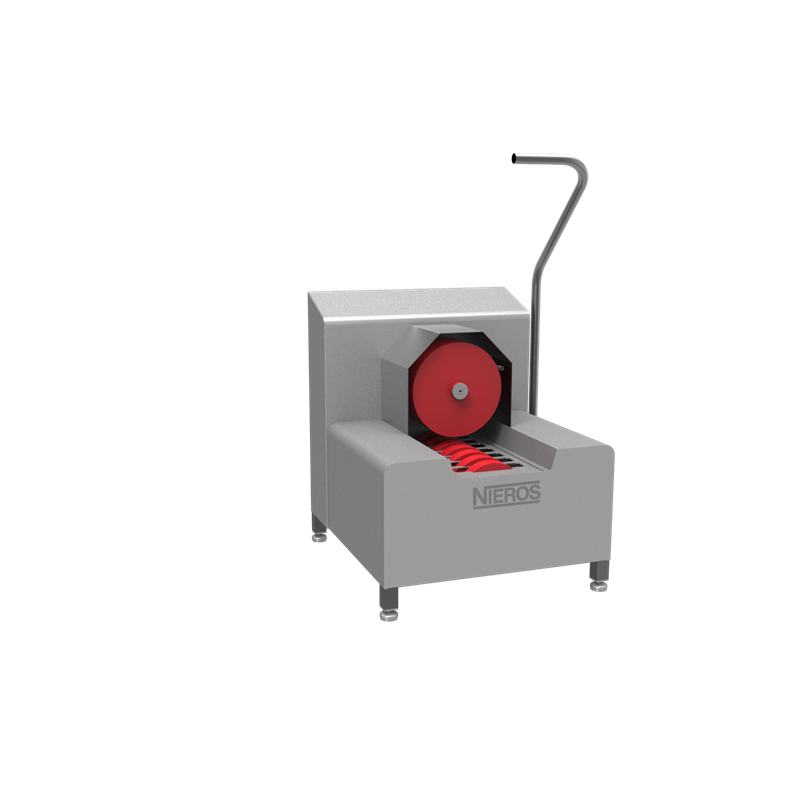

NIEROS® Footwear Cleaning Solutions Provide Measurable Results

A boot cleaner station offers businesses multiple advantages, including important environmental benefits. As more governments push for green transitions, the system’s role becomes increasingly significant. It influences energy consumption, water use, waste reduction, and overall ecological footprint. Effective design and operation deliver measurable improvements. Businesses and industries can select from a wide range of NIEROS® cleaning and drying apparatuses suitable for any production area. All comprehensive solutions are produced in-house, ensuring top quality.

A shoe cleaning machine is a practical solution for controlling contamination in harsh industrial settings. This straightforward investment strengthens hygiene, productivity, and workplace safety. By keeping contaminants out, it enhances compliance and reduces preventable risks. Choosing the right footwear station ensures a cleaner facility and long-term peace of mind.