Shoe sanitizer systems reduce contamination risks without disrupting daily workflow. They ensure contaminants are removed before personnel enter sensitive areas, supporting safer operations, cleaner environments, and long-term regulatory compliance as part of a comprehensive hygiene strategy. A shoe cleaning station has a measurable impact on operational stability by controlling contamination pathways, meeting required standards, improving worker safety, and reducing financial risk associated with hygiene failures.

A shoe sterilizer also directly influences operating costs and overall performance. Its impact extends to quality outcomes, workforce movement, and the establishment of a strong hygiene culture. Long-term cost efficiency is supported through sustainability and scalability, as footwear cleaning machines, when used correctly, help lower emissions and contribute to circular economy practices.

The Operational Importance of a Shoe Sterilizer

A shoe sanitizer is essential in industrial environments where contamination control is critical. Footwear is a primary source of pathogen, debris, and bacteria transfer between hygiene zones. Contaminants adhere to soles and treads and can remain active for extended periods. To prevent cross-contamination, many facilities establish clearly defined hygiene zones where personnel disinfect footwear before entering sterile areas. Reducing cross-zone contamination helps preserve environmental integrity and ensures optimal safety for both staff and consumers.

Sanitizing equipment plays a significant role in industrial hygiene strategies. It prevents microbial contamination that poses serious operational and safety risks while supporting compliance with strict regulations, standards, and legal requirements. Consistent hygiene practices also reduce slip and trip hazards and help reinforce a strong safety culture. A shoe sterilizer is therefore a fundamental element of the rigorous hygiene regimes required in the food, pharmaceutical, and chemical industries.

A Shoe Cleaning Station Designed for Industrial Hygiene

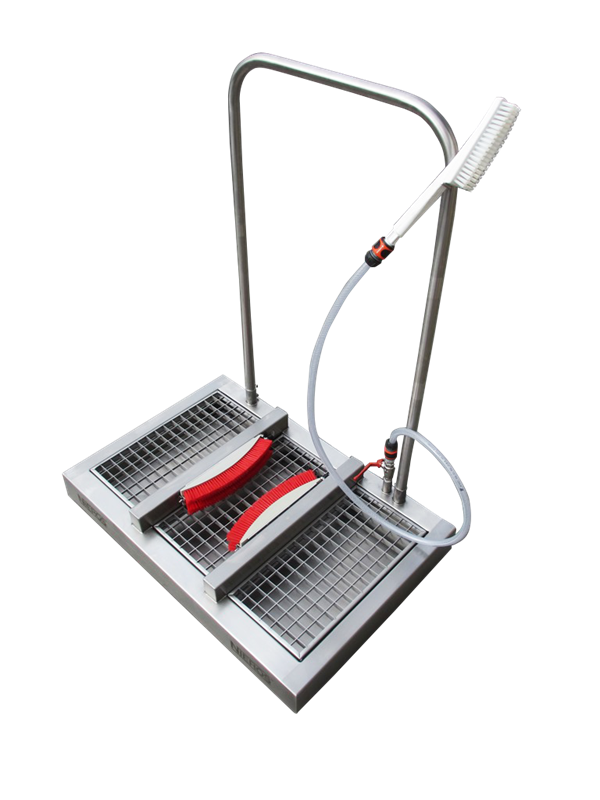

A shoe sanitizer enables effective footwear hygiene in a cost-efficient and highly reliable manner. It is often integrated into a station that can be customized to match a facility’s specific requirements. The station features a hygienic design, height-adjustable construction, and a wide range of cleaning-line lengths and brush types. Brushes can be replaced easily without tools and configured to clean the sides, soles, or the entire shoe. This solution ensures fast operation while minimizing energy consumption.

Manufactured from premium stainless steel, NIEROS® equipment performs reliably in industrial environments with rigorous hygiene requirements. Shoe cleaning station models vary, with some allowing users to adjust the cleaning process based on contamination levels. The equipment supports a wide selection of add-on units that can be combined with base configurations. It is adaptable to different electrical power distributions, complies with HACCP, IFS, and NSF standards, and is produced in-house to maintain consistent quality control.

The Cost Efficiency Benefits of a Shoe Sterilizer

A shoe cleaning station with a sterilizer influences both business operations and long-term efficiency. The movement of personnel across multiple hygiene zones presents an ongoing challenge that can compromise operational continuity. Introducing a structured footwear cleaning station provides a systematic intervention at key transition points and becomes an essential component of the hygiene infrastructure. Installing a footwear cleaning station affects several operational areas, including maintenance and servicing. High-quality stainless steel construction, combined with regular maintenance, ensures a long service life and prevents avoidable equipment failures.

Sustainability objectives also play a growing role in investment decisions. NIEROS® solutions are designed to consume minimal energy and water, supporting responsible resource use and delivering measurable cost savings over time. A shoe sanitizer operates automatically and accelerates sanitation procedures. Faster hygiene cycles reduce bottlenecks, save time, and improve overall productivity across the facility.

12 Environmental Benefits of Using Footwear Sanitization

A shoe sanitizer is a vital tool within an effective contamination control strategy. Industrial operations often face the challenge of maintaining strict hygiene standards while meeting environmental responsibilities. As a manufacturer, we focus on delivering equipment that supports both objectives by offering measurable environmental advantages, including:

- Reducing contaminants that pose an environmental burden when they accumulate in soil

- Improved containment and handling of contaminants

- Water conservation through controlled use

- Enhanced resource and operational efficiency

- Optimized use of disinfectants and chemicals

- Controlled dosing and targeted application of disinfectants

- Reduced need for full-area wash-downs following contamination events

- Energy savings through efficient operation

- Minimized generation of solid waste

- Measurable environmental performance indicators

- Alignment with regulatory and environmental expectations

- Support for long-term sustainability strategies

By integrating environmental considerations into hygiene infrastructure, facilities can reduce their ecological footprint without compromising operational safety. These benefits contribute to responsible industrial practices while supporting efficiency, compliance, and long-term resilience.

A shoe cleaning station features that enhance efficiency and safety

A shoe sanitizer equipped with the right features significantly improves efficiency and safety. One of the most important elements is a purpose-driven design that begins with a clear understanding of contamination risks, traffic patterns, and footwear types. Automation is essential, allowing personnel to move through the system continuously, even during high-traffic periods. Safety is further supported by consistent disinfectant dosing, full sole and tread coverage, and integrated brush systems. A footwear cleaning station with an ergonomic walk-through design helps prevent slips and falls, while monitoring features improve reliability and operational control.

Investing in an industrial shoe sterilizer and a footwear cleaning station is a proactive step towards safer and more hygienic facilities. These systems reduce contamination risks at entry points while supporting compliance with industry standards. With dependable footwear sanitation in place, businesses can protect personnel, products, and long-term operational integrity.