Transport system is crucial for maintaining seamless operations both internally and externally in today's fast-paced business world. For companies looking to optimize their production processes, industrial conveyor systems and automated conveyors systems offer a myriad of benefits.

Investing in a robust grid, particularly industrial and automated conveyor systems, is a strategic move for companies aiming to enhance their operational efficiency and stay competitive. These structures not only streamline internal processes but also contribute to better external logistics, ensuring timely delivery and customer satisfaction.

By understanding the importance and benefits of a transport system, potential buyers can make informed decisions that will lead to significant improvements in their production capabilities and overall business performance. Whether in manufacturing, retail, or any other sector, the right automated conveyors systems can be game-changing in achieving operational excellence and sustainable growth.

Understanding a transport system in a company

A transport system in a company refers to the infrastructure and processes involved in the movement of goods, materials, and products within and outside the organization. Internally, it encompasses everything from moving raw materials to different production stages, to handling finished products ready for distribution. Externally, it involves the logistics of delivering products to customers, suppliers, or other stakeholders.

The importance of efficient automated conveyors systems cannot be overstated. They ensure the smooth flow of operations, reduce downtime, minimize handling costs, and improve overall productivity. Companies that invest in robust automated conveyor systems can expect enhanced operational efficiency, better inventory management, and increased customer satisfaction due to timely deliveries. Additionally, an optimized transport system contributes to better resource allocation and utilization, allowing businesses to adapt quickly to market demands and changes. This adaptability is crucial for maintaining a competitive edge in today’s dynamic business environment. By reducing bottlenecks and streamlining workflows, an effective structure also supports sustainable growth and scalability, positioning companies for long-term success.

The role of industrial conveyor systems

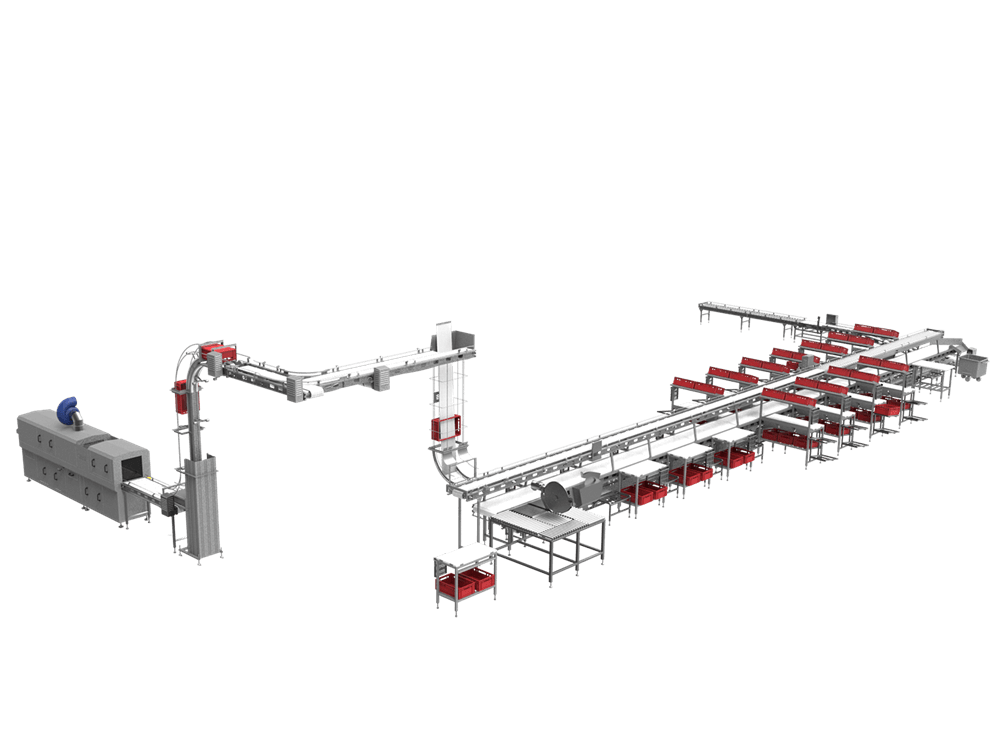

Industrial conveyor systems are integral components of internal transport systems in manufacturing and production facilities. These structures consist of various types of conveyors, including belt, roller, and chain conveyors, designed to move materials quickly and efficiently across different stages of production. The benefits of industrial conveyor systems are numerous.

Conveyors streamline the movement of goods, significantly reducing the time taken to move items from one point to another. By automating material handling, conveyors reduce the need for manual lifting, thus lowering the risk of workplace injuries. Conveyors provide steady and reliable transportation, ensuring products are handled with care and precision, leading to uniform quality. Industrial conveyor systems can be customized and scaled according to the needs of the production facility, making them versatile and adaptable. Additionally, these structures can be integrated with other automated technologies, such as robotic arms and smart sensors, further enhancing efficiency and productivity.

Traits and benefits of automated conveyor systems

Automated conveyor systems take the benefits of traditional conveyor systems to the next level by incorporating advanced technology for enhanced performance. There are some key traits and benefits of automated conveyor systems. Automated structures operate at higher speeds compared to manual processes, significantly boosting throughput and productivity. Automation reduces human error and optimizes material flow, leading to more efficient and streamlined operations. Automated conveyors often use energy-efficient motors and smart technology to minimize energy consumption and reduce the carbon footprint of manufacturing processes. While the initial investment in automated structures may be high, the long-term financial benefits are substantial. Companies save on labour costs, reduce waste, and enhance production efficiency, leading to better ROI. Advanced automated structures come with integrated software that allows for real-time monitoring and control of the production process, enabling quick adjustments and better management.

.jpg)

Sectors that benefit most from automated conveyor systems

Several sectors can significantly benefit from investing in automated conveyor systems. From automotive to electronics, automated conveyors streamline the production line, enhance quality control, and boost overall productivity.

Automated conveyors systems are essential for fast and accurate order fulfilment, helping companies meet customer expectations for quick delivery. These structures ensure hygienic and efficient handling of products, maintaining quality and safety standards. Automation in pharmaceutical manufacturing ensures precision and compliance with regulatory standards, enhancing product reliability. Automated conveyors optimize the sorting, packing, and dispatching processes, improving efficiency and reducing errors.

Nieros is a prime manufacturer of industrial and automated conveyor systems, renowned for its innovative solutions and exceptional quality. With decades of experience in the industry, company combines cutting-edge technology with robust engineering to deliver conveyor structures that meet the highest standards of performance and reliability. The commitment to customer satisfaction is evident through the tailored solutions, ensuring each structure is customized to the specific needs of their clients. Additionally, Nieros offers comprehensive after-sales support and maintenance services, guaranteeing optimal operation and longevity of their structures. The expertise and dedication make Nieros a trusted partner for businesses seeking to enhance their operational efficiency and productivity.