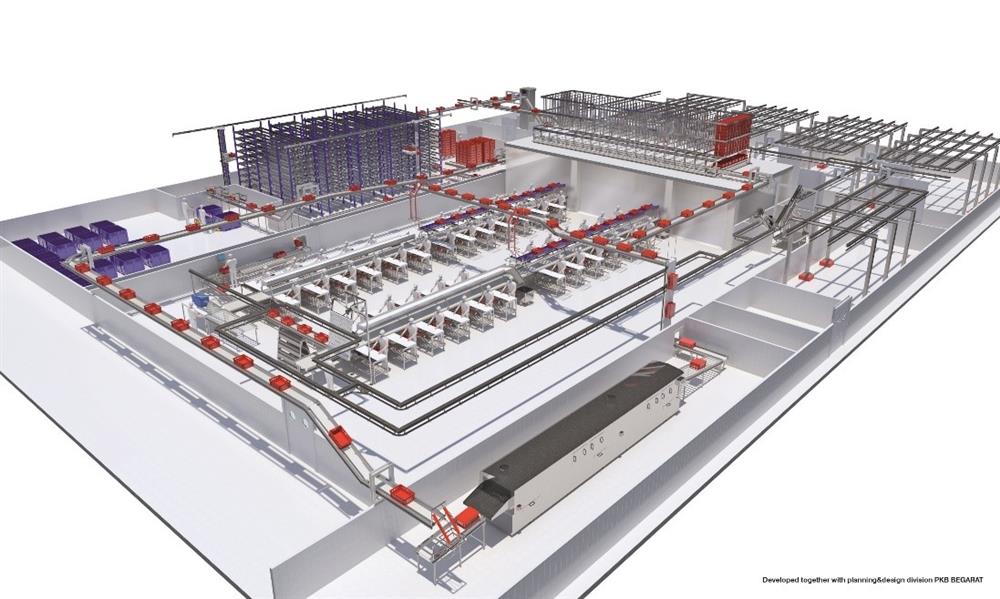

Warehouse automation systems are designed to fit seamlessly within any facility. User-friendly and ergonomically optimised, they operate in various modes, ensuring maximum space utilisation while optimising time and cost. Flexible configurations, accurate inventory control, effective traceability, and efficient order picking enhance overall performance, meet the strictest hygiene standards, and guarantee smooth inventory management.

Installing industrial storage systems within an operation minimises human error, improves accuracy, provides real-time visibility, and ensures scalability, all while accelerating picking and packaging processes. An automated warehouse system helps prevent stock-outs, supports replenishment, and stabilises daily workflows.

Automated Warehouse System for Precision and Regulatory Compliance

Warehouse automation systems combine advanced equipment, sensors, software, and robotics. Each machine has a defined role, enabling repetitive, high-volume tasks to be carried out with precision. Modern technology delivers consistent outcomes while removing bottlenecks between processes. It analyses procedures and data, recognises patterns, and provides results-driven optimisation. Extensive data combined with informed decision-making allows rapid reconfiguration when needed.

Sustainability is increasingly shaping global commerce, with warehouses being major contributors to environmental impact. Reducing errors and returns while lowering transport emissions helps depositories minimise their ecological footprint. Industrial storage systems serve diverse sectors, each with specific requirements and stringent regulations. Innovative machinery ensures reliable supply, regulatory compliance, better space utilisation, and reduced delays.

Scaling Industrial Storage Systems for Growth and Efficiency

An automated warehouse system is a strategic choice for facilities when demand begins to exceed manual capabilities. Mechanisation should be implemented once there is sustained growth and before the warehouse reaches its breaking point. Scalability becomes crucial when growth aligns with strategic goals such as expanding product ranges, improving space efficiency, increasing throughput, enhancing accuracy, or entering new markets. When selecting equipment, businesses must have a clear understanding of both current and future demand.

Scalability also depends on warehouse layout and architecture. It is essential that facilities choose modular warehouse automation systems, as these solutions allow expansion without major disruptions or costly rebuilding. When scaling up, designing processes first—rather than focusing solely on equipment—is paramount. A well-defined and structured process ensures optimal efficiency and maximises productivity. Mechanisation should be introduced as conditions change, protecting the business during periods of growth or disruption. Aligning robotisation with physical infrastructure is key to maintaining long-term performance and enabling smoother future expansion.

The Rise of Mechanization in Modern Warehouses

Warehouse automation systems have transformed depositories both structurally and operationally. Static storage spaces have become dynamic environments with continuous flow and consistent cycle times. Advanced software allows companies to manage inbound receipts, storage, picking, and dispatch. Integrated operational solutions ensure high-volume order fulfilment, reduced travel time, and increased pick rates. With mechanisation, layouts become more adaptable, operations gain flexibility, and businesses can move goods seamlessly. It also enables workflow reconfiguration without extensive construction, making it ideal for product changes or seasonal demand.

Mechanisation has also reshaped how space is valued and designed. Industrial storage systems allow more cargo to be stored per square metre, thanks to widespread vertical storage. Modern industrial buildings are designed to support mechanisation, featuring reinforced floors, high ceilings, and built-in fire protection. While machines perform labour-intensive tasks, personnel focus on supervision, data analysis, and maintenance coordination. Consequently, modern depositories rely on close collaboration between people and mechanised solutions.

Optimising Warehouse Operations Through Automation

Warehouse automation systems streamline operations, increase storage efficiency, and provide accurate, dependable inventory. At NIEROS®, we develop customisable solutions that integrate seamlessly into both small and large spaces. The machines can be operated manually or automatically and feature an ergonomic design that improves product quality, boosts productivity, and enhances hygiene.

Facilities can select from a gravitational system, a pick-and-place system, or a fully automated warehouse system, depending on available space, storage capacity, and product type. Multiple operation modes are also available to suit specific workflow requirements.

NIEROS® Industrial Storage Systems Maximise Space and Time-Cost Optimisation

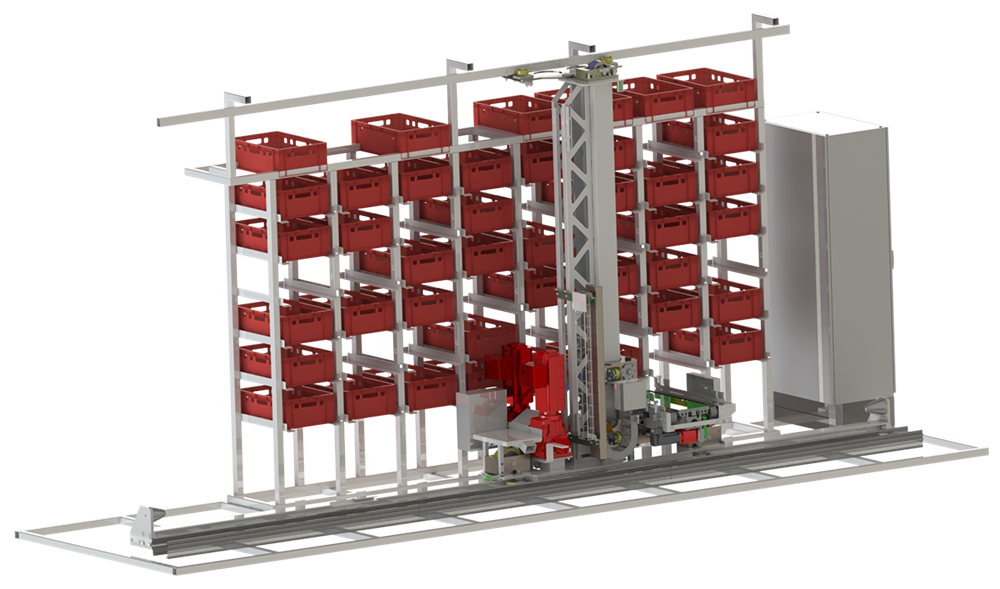

Warehouse automation systems by NIEROS® are tailor-made to meet a company’s specific requirements. Businesses can choose from empty crate, full crate, and pallet solutions. The empty crate system is designed to store clean Euro stacking containers or plastic crates and features multiple entry and exit points, with customisable capacity and dimensions.

Full crate and pallet solutions are available in three configurations: gravitational, pick-and-place, and fully automated warehouse system. The gravitational system suits small storage areas with limited space, pick-and-place handles heavy loads in compact facilities, and a fully automated warehouse system meets the demands of larger storage operations.

Effective depository management is crucial for thriving in today’s fast-paced industrial environment. By implementing efficient systems and maintaining clear communication across operations, companies can improve accuracy, reduce delays, and enhance long-term resilience, supporting consistent and scalable performance.