Warehousing and logistics involve planning and coordinating the movement of goods. They also encompass inventory flow planning, order fulfillment, information exchange, and distribution. Logistics ensure that cargo travels from one point to another in a controlled and traceable manner. Because warehousing facilities operate as controlled environments, they should be designed with careful planning and precise attention to detail. Adequate planning maximizes space utilization, clears pathways, and guarantees accessibility. A well-designed setting provides the flexibility to adapt to changes in inventory needs and support business growth.

Innovative warehouse storage solutions track every item in the warehouse. They come in various configurations to meet specific operational needs and help ensure your company complies with regulations, including emerging initiatives such as sustainability. As customer expectations continue to grow, product lines expand, and suppliers demand faster throughput, these solutions become essential for maintaining efficiency and accuracy.

Warehouse Management Improves Operations

Warehousing and logistics enable products to move efficiently from manufacturing facilities to distribution centers and ultimately to end customers. While these disciplines are distinct, they are closely interlinked. Both are essential for modern commerce, and a company’s competitiveness often depends on how well it understands and manages them. Warehousing encompasses the storage, handling, and oversight of cargo within industrial facilities.

Depots serve a variety of functions that are vital for smooth supply chain operations. When cargo arrives, personnel unload it from trucks and inspect it for quality, quantity, accuracy, and regulatory compliance. Goods are then placed into designated zones and assigned to optimal storage locations using warehouse storage solutions. Maintaining consistent oversight of inventory levels is critical, particularly when preparing goods for further distribution or production. Following order picking and preparation, staff provide additional services such as labeling, repackaging, or palletizing before dispatching items.

9 Benefits of Implementing Warehouse Storage Solutions

A warehouse management system is a critical component in a supply chain, designed to control and enhance operations within a depository. It enables organized management of inventory, processes, data, and labor, while the equipment ensures accurate storage, movement, and real-time tracking of materials. Installing a warehouse management system offers numerous benefits, including:

- Tracking the location, quantity, status, and movement history of every product

- Facilitating receipts and flagging discrepancies

- Optimizing picking and packing processes

- Verifying shipping documentation and ensuring cargo is loaded correctly

- Improving labor management

- Enhancing space utilization

- Supporting cycle counting and auditing

- Managing returns efficiently

- Integrating seamlessly with automation

Innovative technology in warehousing and logistics enables businesses to comply with regulatory requirements while maintaining high levels of customer satisfaction.

Hidden Costs of Not Using an Advanced Warehousing System

Warehousing and logistics often operate without a proper system, relying solely on paper pick lists and spreadsheets. In modern depositories, every second counts. Consumers and suppliers expect fast service, and businesses that cannot provide it risk falling behind in a dynamic market. The absence of modern equipment generates hidden costs that gradually accumulate. These costs are often invisible, appearing in errors, delays, and lost opportunities.

One of the most common hidden costs stems from inefficient workflows. Such issues create delays, bottlenecks, and reduced productivity. Even minor interruptions slow throughput and increase the need for extra labor hours. Low morale can lead to picking errors, resulting in returns and a significant financial burden. When warehouse storage solutions are lacking, stock imbalances occur, either excess inventory or piles of slow-moving items, leading to poor space utilization. Additionally, inadequate data can result in penalties, higher maintenance costs, and communication breakdowns.

Warehouse Storage Solutions: 7 Planning Essentials

Warehousing and logistics must incorporate state-of-the-art equipment and innovative technology to remain competitive. These solutions are essential for smooth operations and directly impact productivity, efficiency, and profitability. Without proper planning, companies risk bottlenecks, increased costs, and poor customer satisfaction. There are several reasons why solutions should be carefully and precisely planned, including but not limited to:

- Customization ensures space optimization, maximizing depository capacity

- Proper storage planning improves control and accuracy

- Adequately organized storage facilitates smoother restocking and inventory counts

- Enhancing workflow reduces labor costs and increases productivity

- Saving space, workforce, and operational expenses leads to significant cost reduction

- Tailor-made solutions offer flexibility and scalability

- Swift adaptation to modern trends such as automation, sustainability, and AI

Warehouse Management Systems Boost Productivity

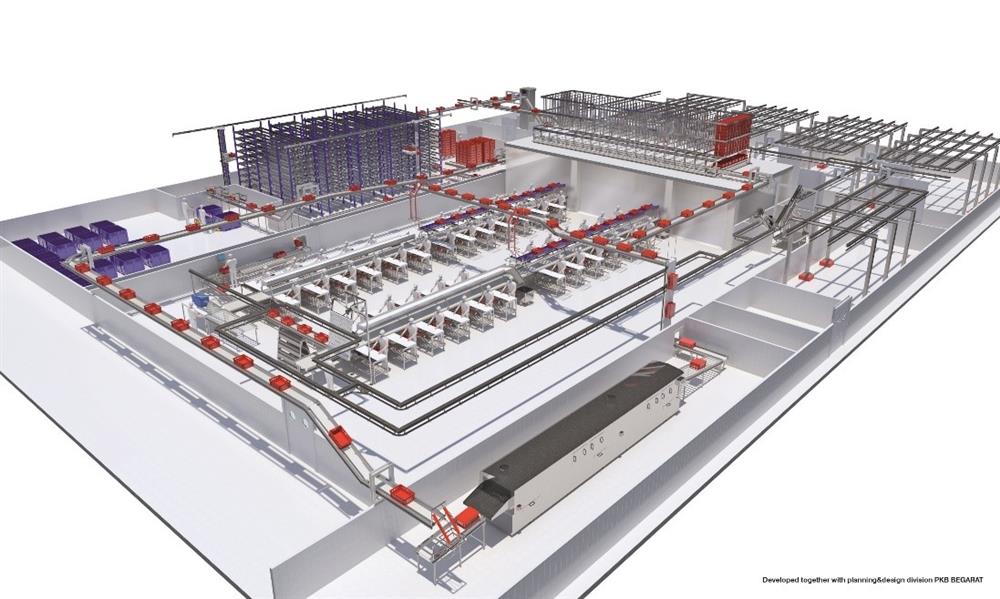

Warehousing and logistics facilities need an optimized layout. The way the space is designed directly impacts overall costs, performance, and operational effectiveness. Poorly planned settings can result in wasted space, bottlenecks, unnecessary movement, and increasing expenses. A good layout begins with analyzing and understanding the facility’s needs. Once inventory requirements are identified, the facility should be organized to ensure optimal flow and maximum efficiency. Proper picking and packing stations are essential, as is efficient traffic flow. By incorporating technology, storage spaces are prepared for future scalability.

As logistics challenges continue to grow, strong warehouse management provides the structure necessary for sustained operational effectiveness. Businesses that invest in scalable systems set themselves up for smoother workflows and improved results. This forward-thinking approach enhances reliability, reduces costs, and strengthens overall supply chain performance.