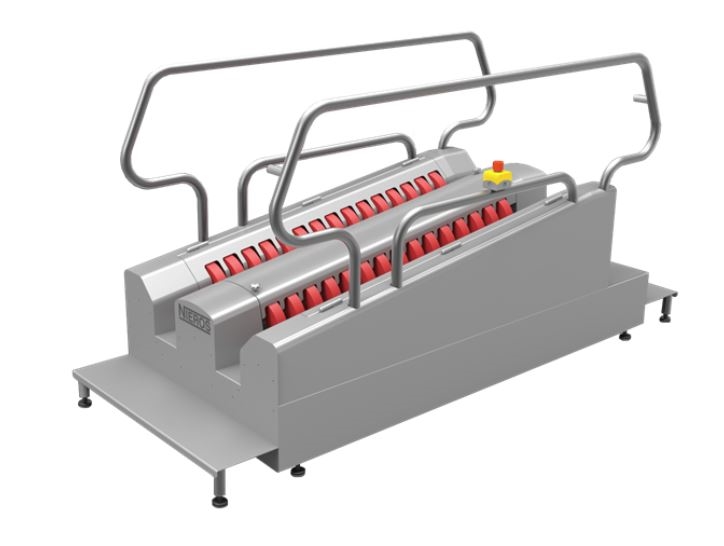

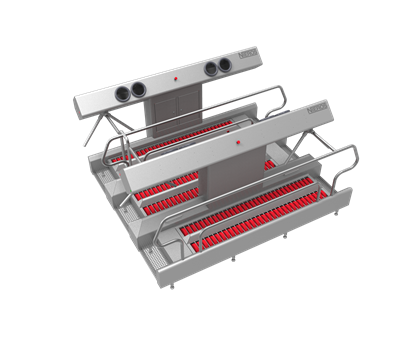

A boot cleaner station is a comprehensive hygiene solution designed to meet the specific needs of your facility. A high-quality shoe cleaning machine must combine precise water control, effective scrubbing, and integrated disinfection. It should be durable and engineered to withstand heavy use and harsh environments. The machinery must deliver consistent performance throughout long shifts and repeated operating cycles.

NIEROS® equipment is made from sustainable materials, features a height-adjustable hygienic design, and is available in various cleaning line lengths and brush types. Our footwear washing systems include a shoe sanitizer, providing optimal hygiene and efficient water delivery. This ensures the equipment runs smoothly throughout the day while supporting sustainability goals.

Top 15 Features of a Shoe Cleaning Machine

A boot cleaner station is customized to ensure the highest hygiene standards and safety. It plays a critical role in contamination control, so selecting the correct features supports consistent daily operations without disruption, guarantees regulatory compliance, and enhances overall performance. Key features to consider include:

- Durable materials and components that withstand harsh surroundings

- Water delivery and control

- Integrated disinfection capability

- User-friendly design and ergonomics

- Safety-focused engineering

- Waste and debris management

- Adjustable washing programs

- Compact and space-efficient design

- Easy maintenance and service access

- Energy efficiency and sustainability

- Compliance with industry standards

- Long service life

- Smooth integration into hygiene zones

- Noise control

- High-performance brush system

Brushes and Nozzles: Key to Shoe Cleaning Machine Performance

A shoe sanitizer does more than provide disinfection. It removes debris, dirt, pathogens, and other residues from footwear before personnel enter or exit a sterile zone. Brushes and nozzles are the two main components that determine how effectively contaminants are washed away. Since industrial footwear accumulates many harmful pathogens, optimal cleaning performance follows three essential steps: mechanical washing breaks adhesion, hydraulic force lifts contaminants, and continuous rinsing washes them away.

Rotating brushes apply steady friction to dislodge dirt, and their type and placement directly influence overall cleaning performance. A well-engineered solution avoids missed areas by overlapping brush paths and maintaining consistent pressure throughout the cycle. Brush rotation speed ensures steady contact and affects disinfecting efficiency, while pressure impacts boot longevity.

Nozzles of a boot cleaner station provide the water flow that activates and completes the cleaning cycle. They deliver wide coverage across flat surfaces and maintain stable water pressure to ensure uniform washing in every cycle. Coordinated operation between brushes and nozzles prevents recontamination and reduces cycle time.

Water Efficiency in Modern Footwear Cleaning Equipment

A boot cleaner station is essential in any industrial facility. With most governments advocating for a green transition, sectors face increasing pressure to reduce resource consumption. That is why our engineers developed water recycling and energy-saving solutions. Water dissolves and lifts debris, maintains surface hygiene, lubricates brushes, and transports contaminants. Older machines relied on continuous water flow, but contemporary solutions use controlled cycles with sensors, pumps, and directional jets. Water activates as soon as a staff member steps onto the platform, providing a strong washing effect while using minimal water.

Water recycling technologies reduce the load on wastewater systems and lower overall consumption. To preserve water quality, regular maintenance is required. It is important to note that regulatory standards influence the water consumption of a shoe cleaning machine, especially in industries where hygiene is critical.

Maximizing Workflow with a Shoe Sanitizer

A shoe sanitizer is often a core component of a footwear washing station. Industrial facilities operate around the clock, and poorly designed hygiene zones can create unnecessary slowdowns. At NIEROS®, we developed state-of-the-art washing equipment with a high-throughput design that processes a large volume of staff in continuous succession. Elongated brushes and extended platforms ensure staff members move forward without hesitation. We optimized workflow by shortening the cycle while maintaining the same high level of disinfection. Fast-rotating brushes and precisely calibrated nozzles work simultaneously to guarantee a smooth sequence and fluid personnel movement.

Automated technology initiates cleaning instantly, provides consistent results, and avoids delays. It also ensures uniform compliance as staff follow strict hygiene protocols. To achieve optimal safety and flexibility, a boot cleaner station is customized to meet the facility's specific needs. It can also be integrated with other solutions, including hand-washing stations.

How a Shoe Sanitizer Cuts Operational Costs

A boot cleaner station with a sanitizer supports workplace hygiene, regulatory compliance, and enhances safety. While it may seem like a small operational detail, it plays a crucial role in reducing avoidable costs. These costs can arise from product quality issues, equipment longevity, labor, maintenance, and waste handling. Automated disinfecting equipment provides rapid washing while reducing the risk of contamination and associated losses. Sterile footwear also lowers maintenance costs across the facility, optimizes water usage, and minimizes penalties and audit expenses.

An industrial shoe cleaning machine helps maintain a pristine work environment with minimal effort from staff. Consistent operation allows facilities to meet strict hygiene expectations without slowing productivity. Selecting the right model ensures long-lasting reliability and improved compliance.