A boots washer is indispensable in environments where hygiene is non-negotiable. Work footwear provides structural support, insulation, protection, and optimal safety. However, shoes can carry chemicals, microorganisms, soil, and organic residues, meaning each step may introduce new contaminants. Industrial settings face increasing demands for consistent sanitation control.

The performance of a shoe cleaning machine depends on its design, the disinfecting agent, its mechanical components, and its operating speed. Because speed is crucial in busy facilities, the machine must be well-engineered, and the flow rate must be set correctly. Flow rate affects regulatory compliance, chemical and water consumption, energy use, throughput, and user experience. A high-quality boot cleaner enhances workplace hygiene and keeps harmful materials contained within designated zones.

Optimal Operating Speed for a Shoe Cleaning Machine

A boots washer cleans footwear and ensures sterile entry and exit zones. The operating speed refers to how quickly staff move through the solution during the washing process. This is measured by the time it takes to complete the disinfecting cycle for one pair of shoes. The speed of the procedure impacts hygiene, energy consumption, and personnel comfort.

Several factors influence maximum speed, including footwear type and surface complexity, contamination levels, brush design and configuration, flow rate, and disinfecting fluid properties. Speed is also affected by product design, regulatory and hygiene requirements, mechanical constraints, employee safety regulations, and ergonomics.

While exact operating speeds vary by apparatus and contamination level, a boot cleaner typically sanitizes footwear in 10 to 30 seconds per cycle. This duration may also depend on whether the machine includes a hand washing solution. The most practical equipment is highly flexible, modular, and engineered to operate efficiently and sustainably.

Flow Rate: Key to Boot Cleaner Performance

A shoe cleaning machine must be stable and reliable to prevent cross-contamination. Numerous factors determine its performance, with flow rate being the most vital. Flow rate refers to the volume of sanitizing agent or water passing through the system over a specific period.

Washing is effective only if contaminants are fully removed from shoe surfaces. When the flow rate is too low, debris can get trapped in ridges or seams, increasing the risk of cross-contamination. If the flow rate is too high, it provides enough force to remove all particles from textured surfaces.

It is essential to calibrate the flow rate according to the facility, the type of shoes, and the hygiene standards. Staff can move through the boots washer efficiently without slowing the workflow. Proper calibration directly impacts throughput, maintaining a continuous disinfecting cycle, reducing water and sanitizing agent use, and upholding strict hygiene standards.

10 Engineering Factors That Influence Flow Rate

A boots washer relies on the precise distribution of water, washing agents, or sanitizing agents to remove debris, dirt, bacteria, and other contaminants from footwear. To ensure smooth operations, the equipment must be carefully planned. Various engineering factors determine flow rate and help engineers optimize performance for specific operational needs. The key factors include:

- Pump design and capacity

- Nozzle geometry and placement

- Pipe dimensions

- Valve design and control

- Pressure regulation and system head

- Fluid viscosity and temperature

- Filter and screen efficiency

- Brush and mechanical component interaction

- Environmental and operational conditions

- Integration with other systems

Engineers who understand these factors can design equipment that meets a facility’s specific needs and requirements. Flow rate is critical, as it directly affects the effectiveness and sustainability of industrial footwear washing operations.

Shoe Cleaning Machine Technology That Transforms Safety

A boots washer has a significant impact on a facility’s operational safety and performance. Innovative technology has transformed footwear washing, creating a fast, thorough, and user-friendly sanitation process. Among the many improvements, automation and intelligent control are the most important. Traditional disinfecting practices relied on manual washing, which was time-consuming and often ineffective. By automating the process, combining equipment for both hand and footwear cleaning, and installing safety features such as turnstile-controlled passages, companies can prevent cross-contamination and establish the highest hygiene standards.

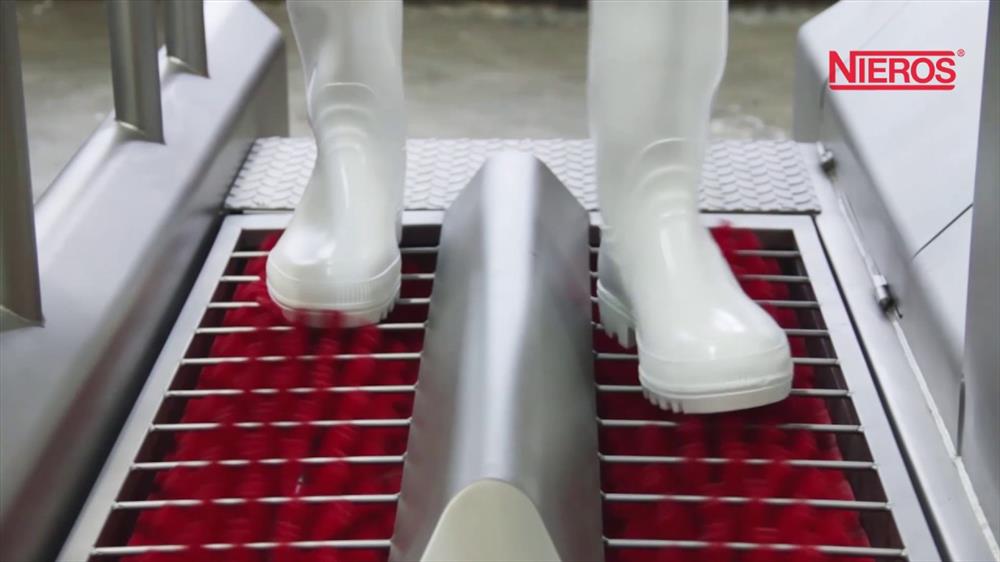

Another key innovation is multi-surface disinfecting. Older boot cleaner models focused solely on sole washing, leaving tops and sides unprocessed. New equipment cleans the entire footwear, providing three-dimensional sanitation that removes dirt completely. Integrated disinfection technology eliminates viruses, bacteria, fungi, and spores, while sustainable engineering minimizes environmental impact.

NIEROS® boot cleaner is a long-term investment in workplace safety

A shoe cleaning machine is a long-term investment in preventing cross-contamination and ensuring compliance with rigorous standards, including HACCP, IFS, and NSF. At NIEROS®, we successfully address a wide range of challenges that our partners face daily in the petrochemical, pharmaceutical, food and beverage, automotive, transportation, agricultural, and chemical industries.

Our engineers understand that a well-designed boots washer enhances both disinfection and personnel safety in high-traffic industrial settings. It keeps contaminants contained and supports regulatory compliance. Choosing the right solution guarantees better workflow, cleaner environments, and long-term operational efficiency.