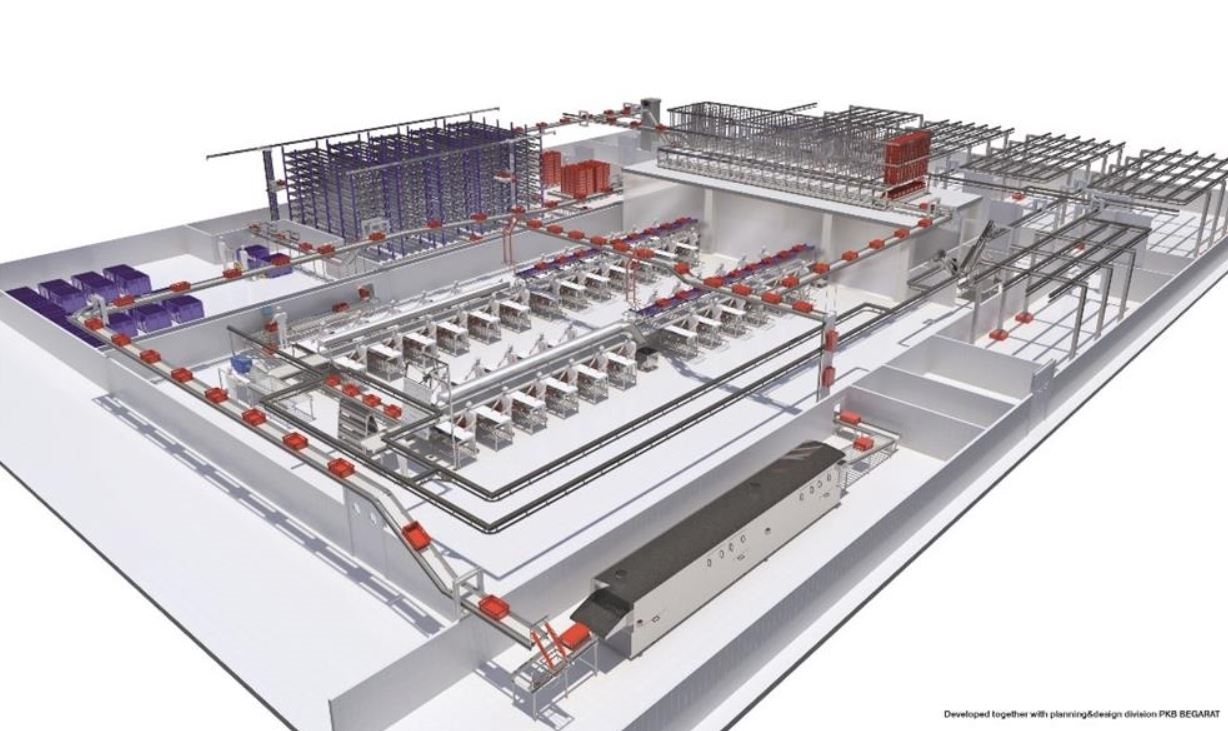

Racking system for warehouse provides a structural framework that ensures inventory organisation, safety, and efficient movement. Its design, structural integrity, configuration, materials, and load capacity must align with operational demands and company workflow. Selecting the correct system requires technical expertise and a clear understanding of long-term operational goals. The equipment should integrate seamlessly with existing processes while optimising the flow of cargo and personnel throughout the facility. Choosing the right warehouse management approach and machinery also requires careful analysis and thorough planning.

Warehouse storage solutions are constructed from premium materials to ensure durability and reliability. Stainless steel offers unmatched strength, corrosion resistance, and predictable structural performance. Effective racking solutions transform a facility into a controlled, safe, and scalable space.

Optimising Warehouse Management with a Racking System

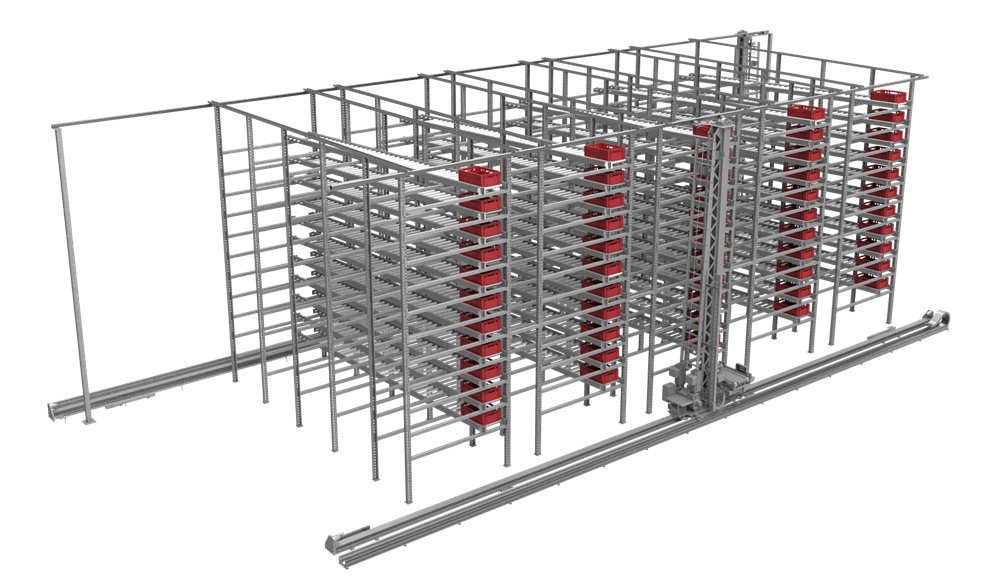

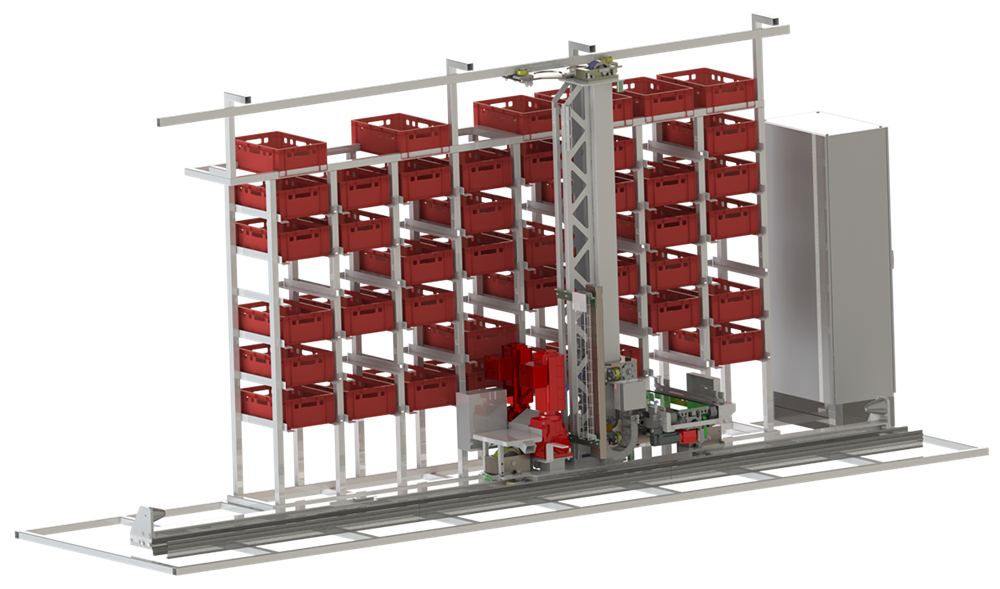

A racking system for warehouse organises inventory and provides optimal visibility for stored goods. It is designed to maximise space utilisation, ensure safe storage, and improve operational efficiency. While it may appear simple, this essential component of an industrial environment is precision-engineered, meets strict specifications, and complies with all necessary regulations. The racks support heavy-duty loads and withstand continuous industrial wear. Composed of vertical and horizontal beams, they create multiple levels of shelving and are usually anchored to the floor to enhance structural rigidity.

There are numerous types of warehouse storage solutions, and a facility should select the one that best meets its operational requirements and industry regulations. Racks are a popular choice due to their efficient use of vertical space, enabling high-density storage that is accessible, identifiable, and secure. Utilising vertical space allows facilities to store more cargo per square metre and provides flexibility across a wide range of racking systems.

Strategic Selection of Warehouse Storage Solutions

Warehouse management is a crucial aspect of any warehouse facility. It ensures that operations run effectively, safely, and sustainably over the long term. Selecting the right equipment shapes daily operations, meets operational requirements, and guarantees future resilience. Before choosing an appropriate solution, facilities should conduct a detailed inventory analysis. The resulting data is essential for system selection, layout planning, and load engineering. After examining pallet dimensions, cargo weight, stock levels, and turnover, facilities can clearly define operational requirements.

Understanding a racking system for warehouse allows informed decision-making, as each solution offers varying levels of accessibility and flexibility. Before implementation, facilities must evaluate space and building constraints, prioritise safety and compliance, and plan for future growth. Equipment should be flexible, compatible with existing infrastructure, and scalable to meet evolving warehouse storage needs.

Choosing the Best Material for Long-Lasting Warehouse Storage Solutions?

Warehouse management relies on equipment that is reliable, compliant, sustainable, and long-lasting. Longevity in warehousing and logistics is not limited to load capacity; it also includes safety margins, dimensional accuracy, and surface integrity maintained over years of mechanical stress and environmental exposure.

The optimal material for a racking system for warehouse is stainless steel. Its unmatched structural integrity, durability, hygiene, and environmental resistance ensure long-term performance in nearly any industrial setting. The exceptional strength comes from its unique metallurgical structure and alloy composition. Stainless steel is recyclable, supporting a circular economy, and a racking system made from this material delivers extended service life and reduced maintenance, providing lasting value for facilities.

Understanding Load Capacity on Warehouse Racks

A racking system for warehouse has a defined load capacity that directly affects productivity, regulatory compliance, insurance, and safety. Each rack, shelf, and aisle relies on a clear understanding of the weight it can safely support. Long-term operational resilience depends on precise figures, and misjudging them can expose personnel, the facility, and stored goods to unnecessary risk. The load capacity determines the maximum weight a racking solution can safely bear under given conditions.

Load capacity is critically important and cannot be overlooked. Overloading racks may lead to structural failure, potentially putting staff at serious risk. Accurate capacity information also guides how inventory is stored and handled. By understanding these limits, facilities can optimise operations, reduce uncertainty, and maintain consistent handling practices.

Warehouse Management for Efficient Storage

A racking system for warehouse is essential for efficient storage as it supports safe, scalable operations, protects inventory, and optimises space. Warehouses are dynamic environments, and their layout and machinery directly influence safety, productivity, service levels, and costs. At NIEROS®, we understand that efficient storage relies on disciplined use of space, which is why every piece of equipment is tailored to fit the facility and its workflow. A well-organised system reduces time waste and prevents stock from becoming buried, while properly installed racks withstand cargo loads, seismic activity, fire, and other impacts associated with material handling.

Well-designed warehouse storage solutions strengthen the entire logistics chain, enabling faster fulfilment and more reliable service. Companies that prioritise organisation, visibility, and automation can significantly improve operational flow. By implementing these enhancements, businesses remain competitive, reduce operating costs, and improve customer satisfaction.