Racks for storage play a key role in shaping and organising modern warehouses, enabling efficient and cost-effective use of vertical space. Warehouses, industrial areas, manufacturing plants, production facilities, and depots would not function in chaos. Every item must have a defined place within the system, allowing staff to locate and retrieve it without wasting time. Carefully selected steel storage racks significantly enhance both space utilisation and workplace safety. Since most cargo is heavy, the racks must form a stable, reliable, and well-supported load-bearing structure.

Optimised warehouses depend on tailored equipment. Industrial shelving units must align with the facility's layout, handling equipment, inventory type, and load requirements. For maximum flexibility, most systems are modular, which means they can be adjusted or expanded as needs evolve. This modularity allows facilities to scale over time without requiring major investments.

Steel storage racks or shelving: What is the difference, and why does it matter?

Racks for storage or shelves? The selection largely depends on building layout, accessibility, safety requirements, and long-term costs. Choosing between racking and shelving systems is challenging. Picking the wrong one can have considerable consequences. Racking refers to heavy-duty systems engineered for palletised products and high-volume storage. On the other hand, the shelves are manufactured for lighter items, which can be extracted manually.

While each solution has its advantages, steel storage racks are ideal for depositories handling bulk volumes and wishing to maximise vertical storage. There are different types of systems, offering unmatched versatility, flexibility, and longevity. Due to their exceptional engineering, racks can handle heavy loads over extended periods. They support a FIFO (first-in, first-out) system and are ideal for fast-paced distribution.

Industrial shelving units are best for storing small, non-palletised inventory. They offer improved visibility and accessibility, making them especially well-suited for e-commerce fulfilment centres. This equipment also streamlines operations and makes inventory management more intuitive.

Racks for storage and warehouse solutions are a reliable and long-term investment

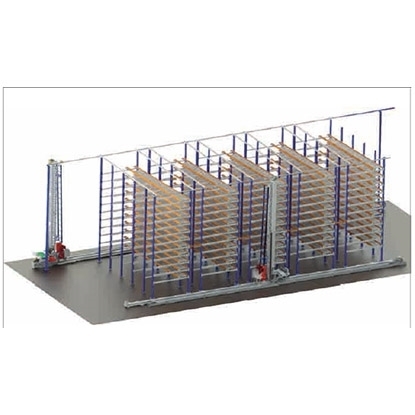

Industrial shelving units, management systems, advanced technology, containers, and bins are all essential equipment in depositories and warehouses. They provide swift and simple storage, while maintaining accuracy and reliable inventory control. At NIEROS®, you can choose between numerous systems with different modes of operation, including:

- Manual operation

- Manual charging and automatic removal

- Automatic charging and manual removal

- Automatic charging and automatic removal

Equipment such as racks for storage can incorporate innovative order-picking solutions, ensuring inventory is quickly accessible and easily traceable. Every NIEROS® warehouse system is tailor-made to perfectly fit each facility, increasing productivity, enabling cost-effective operation, and preventing inefficiencies. Carefully planned storage also uses space to the maximum and improves hygiene conditions. The products comply with all the necessary HACCP, IFS, NSF, and other similar standards. They allow for economical management, flexible configuration, and easy maintenance.

What you need to know about steel storage racks

Racks for storage can be a practical addition to your facility. One of the most important things to know about steel racks is their load capacity. This number refers to how much weight they can safely support. Load capacity is calculated based on several factors, including the type of steel, beam height, pan, floor anchoring, and connection. It is calculated under rigorous standards and thoroughly tested. Exceeding these limits can cause them to collapse.

When installing such a system in any facility, it is essential to anchor it securely to the floor. Proper anchoring prevents tipping and reduces vibration caused by equipment movement, such as forklifts. Steel storage racks must always be anchored, with anchoring requirements varying based on floor type, load capacity, seismic zone, and rack height. Anchor bolts should be appropriately sized, installed to the required depth, and tested after installation to ensure stability and compliance.

It is paramount that the shelves comply with the hygiene and fire safety regulations. A professional must inspect the shelves for signs of damage or overloading. Some signs of usage include bent frames, missing pins, beam dislodgement, and loose anchor bolts.

Design a warehouse with flexibility in mind and use industrial shelving units

Industrial shelving units and depository systems offer specific solutions. They are an incredibly popular choice for space optimisation and are part of every industry handling physical goods. They are widely used across industries that handle physical goods and are essential in depositories, distribution centres, pharmaceutical facilities, food processing plants, and retail environments. As a popular solution for smaller-scale operations and large-volume warehouses, they offer immense adjustability, durability, access, and versatility. They can endure extreme environmental conditions, integrate with existing technologies, and help support warehouse efficiency.

A well-designed system prevents congestion and bottlenecks, reduces travel time, and improves picking efficiency. Racks for storage can be integrated with conveyors, automated retrieval systems, and advanced technology to accelerate inventory flow and ensure high accuracy. Engineered to hold substantial weight, racks can handle inventory of over a hundred kilograms per beam level and even multiple tonnes per bay. At NIEROS®, we continuously invest in our R&D department to deliver products that maximise space utilisation and optimise both time and cost for our clients.